We've added tow brackets to Amy's 2007 Honda Fit. Had them since last year, just never got time to install. Finally had our mechanic - Jim's Auto in Roxborough - do the installation. Now, just need to get the brake & turn lights figured out. On this test tow in a parking lot - worked great!

Travels with Family and Friends in RoadAbode 2.0, Our 2019 Class C Motorhome.

Sharing destinations, travel tips, and recommendations as we pursue our version of the RV lifestyle.

Showing posts with label Upgrade. Show all posts

Showing posts with label Upgrade. Show all posts

Saturday, March 23, 2013

Saturday, June 02, 2012

2012 Project for RoadAbode - Entry Step & Door Window

In the past, my Winter/Spring Projects for RoadAbode have usually revolved around installing "new" things. Past projects included an inverter, new TV and sound system, and new table mechanism to name some favorites. This year's major project was repairing something old. RoadAbode's entry step. Am had noticed that the first step as you come into RoadAbode felt soft on it's right side. So on our Mother's day trip out I lifted the rubber tread and took a peek underneath - and didn't like what I saw.

The wood had dry rotted and was crumbling away. Just like a scab or hangnail in an annoying spot, we started picking and pulling at the wood, and pretty soon saw the extent of the damage. The way it was constructed was pretty cheap too. Three or four layers of plywood built up inside the metal box in front of the battery box and glued to each other, with Elevator Bolts that held the mechanical step in place embedded between the layers. Plywood was neither marine grade or pressure treated. I was looking for the next upgrade of RoadAbode - and looks like it found me! We took out what we could with our on-board toolkit, then cut in a temporary replacement step from one of our older foam interlocking playground pads we use for our "patio". The next few days we formulated our "attack plan". We took measurements and on work day, stopped at Lowes to pickup supplies.

The wood had dry rotted and was crumbling away. Just like a scab or hangnail in an annoying spot, we started picking and pulling at the wood, and pretty soon saw the extent of the damage. The way it was constructed was pretty cheap too. Three or four layers of plywood built up inside the metal box in front of the battery box and glued to each other, with Elevator Bolts that held the mechanical step in place embedded between the layers. Plywood was neither marine grade or pressure treated. I was looking for the next upgrade of RoadAbode - and looks like it found me! We took out what we could with our on-board toolkit, then cut in a temporary replacement step from one of our older foam interlocking playground pads we use for our "patio". The next few days we formulated our "attack plan". We took measurements and on work day, stopped at Lowes to pickup supplies.When we got to RoadAbode, not being a carpenter, I forgot what "Nominal" means when purchasing lumber. So while Am did some cleaning and prep - I went and picked-up another pressure treated board to serve as our new step (at $9 - a cheap reminder in lumber measurements) First, we disconnected the electrical connection for our mechanical step.Am borrowed a Saws-All and after removing what was left of the bad step with a wood chisel, we cut the bolts - which were pretty rusted and not easily accessible. We setup some cardboard and padding for the mechanical step to safely fall on to. I did forget to remove the magnetic switch that let's me know if the step is in or out from the driver seat! (Doh!) After removing the glued-on magnetic switch, I could lift the mechanical step totally out of the way. Test fit the wood. It was two pieces of Pressure Treated Deck, 2X10X25" (Nominal, that made it about 3" think, which perfectly fit. The top one I needed to shave off a 1/2" of width to make the reduced area of the threshold.

Next, we cleaned the box the step had been set into. The steel was in good shape, with only some surface rust. We sanded out the rough spots, cleaned, then Am taped out and painted the interior with Rust inhibitor/neutralizer. That needed to dry for 24 hours, so we cleaned and closed up till next time.

Next, we cleaned the box the step had been set into. The steel was in good shape, with only some surface rust. We sanded out the rough spots, cleaned, then Am taped out and painted the interior with Rust inhibitor/neutralizer. That needed to dry for 24 hours, so we cleaned and closed up till next time.Next time I could take time to work on her was a week later. I was alone on the assembly, as Am had a baby shower to attend. After a few stops, Got to RoadAbode at 11am - a little later than I wanted, but at least it was a beautiful day to work outside. Marked the Step to drill holes for the Elevator Bolts - fit perfectly! Used my car jack to lift the mechanical step in place (too heavy for me to hold AND bolt in place) Worked great in a pinch! Got three nuts on and hand tightened - easy! Except - of course - last nut was the wrong size! Back to Lowes. Felt strange to exchange one nut - but was easy, no cashier involved for that.

Back at Roadabode, fit the top piece of wood over the elevator bolts, then drilled pilot holes and screwed the pieces together using deck screws (something that wasn't done on building the original step apparently) Lastly, I tacked the rubber threshold on the front side, then used Liquid Nails to glue it down, and tacked along the edges.

Reconnected the Mechanical Step electricity and magnetic switch - looks good, sturdy and feels good to do ourselves. Took longer than if I took it in for service, but I used "better" materials, and learned more about how RoadAbode is built!

After feeling good about how the step went together -and still having time - I looked at another small issue RoadAbode was having. The glass in the "house" door kept sliding down and leaving a 1/2" crack at the top. I first used painters tap to secure the outside bezel to the door. Then removed the screws holding the inside bezel. (the bezels connect together and hold the glass in place) Why the glass was sliding is the black bezel has plastic pins that hold the glass in place, and the bottom pins were broken. Also, the silicone caulk needed to be replaced, as it was missing in places. I figured I could cut some more of the foam from the patio tile I used previously, and it would help replace the plastic "pins" on the bottom of the bezel. I glued that in place, removed and re-caulked the bezel - re-inserted the glass, and fit everything back together. I think the glass will stay in place now! By the time I finished cleaning and packing up - it was 4:30pm. Two jobs and RoadAbode should be ready for her next adventure!

After feeling good about how the step went together -and still having time - I looked at another small issue RoadAbode was having. The glass in the "house" door kept sliding down and leaving a 1/2" crack at the top. I first used painters tap to secure the outside bezel to the door. Then removed the screws holding the inside bezel. (the bezels connect together and hold the glass in place) Why the glass was sliding is the black bezel has plastic pins that hold the glass in place, and the bottom pins were broken. Also, the silicone caulk needed to be replaced, as it was missing in places. I figured I could cut some more of the foam from the patio tile I used previously, and it would help replace the plastic "pins" on the bottom of the bezel. I glued that in place, removed and re-caulked the bezel - re-inserted the glass, and fit everything back together. I think the glass will stay in place now! By the time I finished cleaning and packing up - it was 4:30pm. Two jobs and RoadAbode should be ready for her next adventure!

Friday, June 17, 2011

Sunday, June 12, 2011

Saturday, April 18, 2009

RoadTesting the LCD TV

Here's the TV in its "extended" mode. When traveling, it sits in front of the cabinet opening, buckled in, and is still operational using the inverter and switch I installed as one of our first upgrade projects for RoadAbode. It picked up over 100 channels in cable mode at Spring Gulch campground this weekend, a mix of analog and digital. Girls requested that I swivel the viewing angle down, which was pretty easy with the adjustment knob on the back (though I would not want to do on a daily basis - hard to tighten up by hand to my satisfaction)

Am has purchased material and a rod to hang a curtain for inside the old tv cabinet - to conceal the cables and other equipment.

Saturday, April 11, 2009

Upgrade Number two for 2009

Had been looking at ways to update the existing CRT TV in RoadAbode. One way was using an Acer LCD Monitor I had. I researched and then purchased a Digital TV Coverter. picture was beautiful, for Over the Air Channells, but was only picking up the secondary Cable Channels. Plus, hooking up games or the DVD player was problematic. What was suppose to be a "cheap" solution was getting costly. Looking on the web, found a good deal on a LCD 19" Vizio TV. I also purchased a swing arm mount to hang the LCD. Some new cables, and some cable ties and such, totalled out to about $240. Once all was delivers - The install fun began!

First came the removal of the old TV and VCR. One of my objectives was to also move the component switch, electrical, and subwoofer from the cabinet next to the TV, and into the space vacated by it. i also wanted to utilize an old Laptop (since the Vizio has a monitor in) for basic surfing/search functions when at a campground that has wifi and to play mp3s when needed.

Here's the Cabinet Next to the TV - Chock-ful of equipment!He's stuff moved over - still a scramble of wires and cables, but getting there. The subwoofer and a/v auto- switch I added velcro to - so they don't move or slide around.

Wiiring is a little better, and you can see the foam cushioning mounted for the laptop

Saturday, February 28, 2009

RoadAbode's Upgrade for 2009

While at the Valley Forge RV Show in Febuary with Frank, saw a 2008 Jayco Greyhawk. It was a great deal with lots of ammenities. One feature that really struck me was the Greyhawk's "Dream Dinette". The ability to slide into the dinette without hitting the leg of the table, and the ease to raise and lower the table to use the dinette as a sleep area.

The next week, the table was still on my mind, so I started research, both on RV.net and just doing some Google Searches. Found out soon that quite a few manufacturers use the "Dream Dinette" in their models. so I tried to find the company that actually made the mechanism for the table. Took some digging, but finally found on a RV industry website that Cass Hudson Co. has the actual Trademark on it. Emailed, and finally called (when I got no response from email). Spoke to Darren, he gave me specs to decide which of two models would fit RoadAbode.

The Mechanism is $125 plus Shipping.

The next week, the table was still on my mind, so I started research, both on RV.net and just doing some Google Searches. Found out soon that quite a few manufacturers use the "Dream Dinette" in their models. so I tried to find the company that actually made the mechanism for the table. Took some digging, but finally found on a RV industry website that Cass Hudson Co. has the actual Trademark on it. Emailed, and finally called (when I got no response from email). Spoke to Darren, he gave me specs to decide which of two models would fit RoadAbode.

The Mechanism is $125 plus Shipping.

What measurements they needed:

Floor to the bottom of the Window Frame

Floor to the "Cleat" on the bench of the dinette (the Cleat refers to the piece of wood/trim that holds the table in place when you make the dinette into a bed)The mechanism weighs about 16lbs, so Darren said I needed to reinforce the wall.

I took a trip up to RoadAbode, got measurements, called Darren back, and ordered. Within a few days, the "Dream Dinette" mechanism was delivered - What follows is the install process for the new table.

Floor to the "Cleat" on the bench of the dinette (the Cleat refers to the piece of wood/trim that holds the table in place when you make the dinette into a bed)The mechanism weighs about 16lbs, so Darren said I needed to reinforce the wall.

I took a trip up to RoadAbode, got measurements, called Darren back, and ordered. Within a few days, the "Dream Dinette" mechanism was delivered - What follows is the install process for the new table.

The Install

One thing I want to make clear - the steps I'm documenting would probably not be sanctioned by the Carpenter's Union. I can do basic builds, but don't have the skills to do anything advanced.

Package Arrived on Thursday - earlier than expected.

On Saturday, headed up to RoadAbode with tools and the mechanism. On the way, went to Lowes to grab a piece of Wainscoting, screws, some Gorilla Glue, and new screw bits for my drill. Stopped at McD's for a quick lunch, not my usual fare, but close to RoadAbode. Picture above is the last lunch on the "old table" - actually same table,

Here's the Old setup. The leg would get in the way, made it hard to pull out the storage ottoman, and was something we just had to be careful of. Also the brackets were a bit "rickety", a bit worn looking, and tough to get into the bed position

View of the old setup from underneath, The white rectangular part conceals the electric cable from the inverter to the entertainment center.

Electric cable uncovered, and table securing brackets removed.

Wainscoting fitted into the space between the two dinette benches, under the window. Used Gorilla Glue and Screws to secure to the wall. This is to strengthen the wall for the bracket connection.

Once the wall was prepped, I marked a center line on the underside of the table to aid in making sure the bracket mechanism is lined up correctly.

Mechanisim on the floor in the dinette area. Only had to line up two bolts, one for the strut, one for the table support. Doing the one for the strut first is definetly the way to go.

Attached the back end of the mechanism (what attaches to the wall) flush to the bottom of the tabletop. - I moved this later - will show why.

This is the slide track and locking bar. Using the center line I had drawn earlier, I marked holes to drill, then attached the slide bar, with the slide inside.

Here's the lock bar in place, the slide, and slide bar. Went smoothly, but I almost re-positioned because now the table sits 2 inches higher. checked with the boss (Wifey) via phone, she okay-ed, so it stays. =p

This part was not in the instruction manual. The mechanism mounting bracket, causes the table to be approx. 1.5 to 1.75 inches away form the wall. to lessen this distance, and still allow the mechanism to slide, I re-used the elastic wrap the unit came in, and pulled the armature closed. this allowed me to shimmy the bracket back, and once tightened, made the gap between table and wall about .5 or .75 of an inch.

Table up and in!. Still need to finish adding mounting screws (only 2 are holding it to the wall in this picture, there are 13 when it is done. Table now sits at 30.5' tall, use to be 27.5", and converting up and down is a much smoother operation.

Underneath the tabletop, when made into a bed. will need to secure and conceal the electric cable - old way will not work anymore.

The "gap" behind the table. May put a piece of board or something decorative there.

Table up and ready to hold it's next meal, or a good card game. The black item on the table is the volume control for the entertainment center, and also provides a headphone jack. Ties into the speaker system, which is actually a nice sound system (with woofer too) from a computer system.

Got to RoadAbode at 1:30pm, had lunch, got all my supplies together, and started at 2pm. Was done and cleaned up by 6pm. Would have been done faster if I didn't have to take a break when the battery on the drill died. Total cost is under $170.

Cass Hudson did a great job on the instructions, Darren gave great tips and customer service, and the product is well made. Look forward to using this year.

Monday, June 23, 2008

A Bit of a Storm

You may notice the picture in this post is a little different than the previous post. We had to get a new shaderoom. Saturday into Sunday at 8am sharp we had a torrential downpour. We quickly closed up everything, and I sat to enjoy my cup of java, looked out the window, and saw our year-old shaderoom collapsed under the quickly accumilated weight of the water. We went out to use the cover as a tarp to cover best as possible.

Amy and I took a ride out to Walmart and picked up the canopy pictured above On sale, it is a little smaller (100 Sq ft vs. 144Sq ft) but seems stronger and well made. We'll see how it holds up. Def. a good price though, a good bit less that $100, and just as easy to set up as the old one (accordion style frame)

To get online this week, using a Verizon aircard modem from work to connect - just as easy as using my cell as a modem, maybe easier. Nice sitting at the picnic table and checking in at work, researching prices for shade rooms, or just doing a bit of surfing. Quick too!

Few pics from Otter Lake:

The Lake, by the swimming beach

The Lake, by the swimming beach Em on her favorite climbing rock

Em on her favorite climbing rock Em fishing

Em fishing Tammy getting outside Exercise (Tammy is Em's pet Dwarf Hamster)

Tammy getting outside Exercise (Tammy is Em's pet Dwarf Hamster)Saturday, April 21, 2007

Lake-in-Wood Full Day of Fun

Woke around 6:30am, got coffee brewing, and enjoyed the sounds of birds - and just the quietness of the surrounding woods. After some breakfast, Amy & I went for a short bike ride and then got to work replacing 2 cracked roof vents. Each vent was under a Maxxi-Air cover, so Amy took those off on RoadAbode's roof, while I worked inside to remove the internal moulding, screen, and vent mechanism. We did both vents in less than an hour. While we were finishing up , Emily took a spill on her bike - that scared us all (right into a boulder!) She was okay, but shaken up.

A family bike ride was next, and we went to check out the 'Gnome Cafe" - and stayed for lunch. Not too expensive, and good food. Emily enjoyed time on the playground, and we all had ice-cream for dessert.

After lunch, we tried our luck fishing. Emily and Amy also took a paddle boat ride. Good thing, because they helped me out when I got my line tangled up in a partially submerged tree branch.

After fishing, I had a surprise for the girls, an inexpensive remote control plane I had picked up at Radio Shack. Kimberly turned out to be the Best "pilot" - keeping the plane aloft for the longest time, and making some great turns!

While Emily, Kimberly and I played, Amy got together sloppy joes for dinner.

A Campfire with marshmallows and cooked pears made for a great family-time dessert.

A little Cable TV - then off to bed - Great Day - Full of Fun!.jpg)

.jpg)

.jpg)

.jpg)

A family bike ride was next, and we went to check out the 'Gnome Cafe" - and stayed for lunch. Not too expensive, and good food. Emily enjoyed time on the playground, and we all had ice-cream for dessert.

After lunch, we tried our luck fishing. Emily and Amy also took a paddle boat ride. Good thing, because they helped me out when I got my line tangled up in a partially submerged tree branch.

After fishing, I had a surprise for the girls, an inexpensive remote control plane I had picked up at Radio Shack. Kimberly turned out to be the Best "pilot" - keeping the plane aloft for the longest time, and making some great turns!

While Emily, Kimberly and I played, Amy got together sloppy joes for dinner.

A Campfire with marshmallows and cooked pears made for a great family-time dessert.

A little Cable TV - then off to bed - Great Day - Full of Fun!

.jpg)

.jpg)

.jpg)

.jpg)

Saturday, April 14, 2007

Some work before the Storm

Weather is suppose to be bad starting this evening, so the girls, Amy & I went to storage early to replace 2 cracked Vent lids (their under the MaxxiAirs) and fix the 4 prong connector we bent in Kentucky. Ordered all the parts from PPL Motorhomes in Texas. Found out the vents were the wrong type - so only can do the electrical.

Wednesday, March 07, 2007

Too Long

Too Long without a post.

Haven't posted since Beginning of December! Well - Hopefully that should change - We're Heading Out to Long Island Soon!

Stuff has happened, but nothing major. Got some nice Solar Lights for RoadAbode, and a new Shade room, and some leveling blocks. Have visited RoadAbode a few times, ran her genset. Think my air compressor died though, will have to look at that.

Will report from the road soon - Ya-Hoo!

Haven't posted since Beginning of December! Well - Hopefully that should change - We're Heading Out to Long Island Soon!

Stuff has happened, but nothing major. Got some nice Solar Lights for RoadAbode, and a new Shade room, and some leveling blocks. Have visited RoadAbode a few times, ran her genset. Think my air compressor died though, will have to look at that.

Will report from the road soon - Ya-Hoo!

Monday, May 29, 2006

Weekend project

Made from a round of Basswood - first I created a black-n-white image on the laptop, mirrored it and printed out. used the printout to 'rub' the image onto the wood, and used a burning tool to etch the picture in. Pretty good likeness of a "Class C" After etching was done, rubbed with n eraser to get any leftover lines out, and then coated a few times with polyurethane spray. Will use on our next outing!

Saturday, May 27, 2006

Visiting RoadAbode

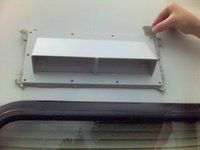

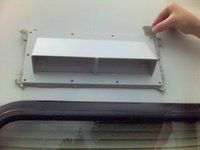

Visited RoadAbode to take care of a few issues. Had gotten the parts in from PPL Motorhomes to fix the oven vent I had broken at Hickory Run, the bay door latch from a few weeks ago, and replace some caulk that looked like it may fail.

The door latch was the easiest of the jobs, just two screws and clean off the old putty, replace with new.

For the oven vent, Amy helped remove the old vent, place the waterproofing putty, and install the new vent.

For the oven vent, Amy helped remove the old vent, place the waterproofing putty, and install the new vent.

After the vent, I went to the rear of RoadAbode and clean off some old caulk on top of the rear curved cap. I filled in with new self leveling sealant.

While I was on the roof, Amy took our bike back home (we temporarily had them inside RoadAbode, and had loaded them into the van when we arrived at RoadAbode this morning.

I finished up, cleaned up and just did some reading, listen to the radio, and enjoyed the scent of the wild roses and honeysuckle behind where RoadAbode is stored. When Amy returned with the girls, had lunch together, and then out for some holiday shopping!

radio, and enjoyed the scent of the wild roses and honeysuckle behind where RoadAbode is stored. When Amy returned with the girls, had lunch together, and then out for some holiday shopping!

The door latch was the easiest of the jobs, just two screws and clean off the old putty, replace with new.

For the oven vent, Amy helped remove the old vent, place the waterproofing putty, and install the new vent.

For the oven vent, Amy helped remove the old vent, place the waterproofing putty, and install the new vent.After the vent, I went to the rear of RoadAbode and clean off some old caulk on top of the rear curved cap. I filled in with new self leveling sealant.

While I was on the roof, Amy took our bike back home (we temporarily had them inside RoadAbode, and had loaded them into the van when we arrived at RoadAbode this morning.

I finished up, cleaned up and just did some reading, listen to the

radio, and enjoyed the scent of the wild roses and honeysuckle behind where RoadAbode is stored. When Amy returned with the girls, had lunch together, and then out for some holiday shopping!

radio, and enjoyed the scent of the wild roses and honeysuckle behind where RoadAbode is stored. When Amy returned with the girls, had lunch together, and then out for some holiday shopping!

Subscribe to:

Posts (Atom)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)